Bag Machine Options: Controls, Add-ons & Upgrades

|

Converting System's offers several options to expand and increase the productivity and safety of your current machines.

|

|

“Clamshell” Safety Guarding System Add-on

These "Clamshell" style guards have been designed for use on new Converting Systems bag machines or various other manufacturers’ shuttle style machines. When an operator flips back the Lexan guard to access the machine, the guard system signals the bag machine to stop production. This then puts the machine in a "safe" mode for the operators to perform set-up, maintenance, or web up the machine. With the ability to mount on many different suppliers machines, these guard systems are an economical way to meet stringent safety requirements. |

|

New! Tool-less Handle Adjustment Assembly Bag Machine operators can now quickly and easily make adjustments to the Teflon curtain without having to stop and find the right sized tool. Also eliminates lost parts. This new tool-less design supports our goal to provide more operator friendly machines to our customers. Place order HERE |

|

|

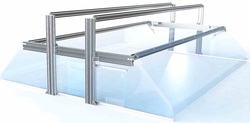

Pinch Roll Edge Guide System/Retrofit

CSI’s Pinch Roll Edge Guide System is designed as a “drop in” system to help guide a web through a bag or pouch machine. Since it does not require the web to be "wrapped" over or under any rollers, it is ideal for film which have fixtures installed that cannot be wrapped over/under any camber rollers. This system uses a laser sensor to accurately monitor the edge of the web. The control unit then makes adjustments to pinch rollers to pull the film in one direction or another. Incredibly easy installation and set-up make this unit an ideal field retrofit on any number of different machines. The solid model (see picture) provides a visual of an installation in the sync. Section of a typical side weld and bottom seal machine - note the section rails used in the model. |

|

Variator Replacement System Retrofit

CSI’s Variator Replacement System allows customers the ability to upgrade only the Tension Variator portion of a shuttle style machine. On many older machines, a worn-out shuttle tension variator becomes inconsistent, allowing film tension to vary greatly during a production run. Inaccurate set-up, and inconsistent tension control cause a large amount of scrap. CSI’s Variator Replacement System transforms the variator system to an electronic line shaft controlled, AC Vector axis. This Vector drive follows EXACTLY the encoder feedback from the machine, then follows EXACTLY the speed of the nip rolls. Whether running 25 FPM or 250 FPM, the servo will follow accurately and deliver consistent film tension. Operators can easily adjust shuttle tension with a simple potentiometer. |